Wire harness: the link that connects the world

Nov 27, 2023

In modern society, the rapid development of electric power, communications, automobiles and other industries is inseparable from a seemingly insignificant but crucial component - the wiring harness. A wire harness, as the name suggests, is a collection of multiple wires bundled together according to certain rules. It is like a link connecting various devices and provides convenience for our lives.

01

Definition of wire harness(100A High-Speed Electric Motorcycle Male And Female Plug Wiring Harness,Unipolar 45A Plug Sheathed Soft Silicone Wire)

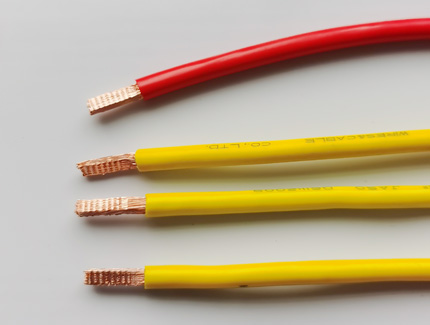

A wire harness(OEM Wire Harness Overall Solution Elbow Power Cord) is a component that bundles multiple wires together according to certain rules. It usually consists of wires, insulation layers, sheaths and other parts. The main function of the wiring harness is to transmit power or signals from one device to another to achieve interconnection between devices.

Wire harnesses are classified mainly according to their application fields and functions. According to application fields, wiring harnesses can be divided into power wiring harnesses, communication wiring harnesses, automobile wiring harnesses, etc.; according to functions, wiring harnesses can be divided into power wiring harnesses, signal wiring harnesses, control wiring harnesses, etc.

Different types of wire harnesses differ in structure and performance, but they all have a common goal, which is to provide stable and efficient power or signal transmission for equipment.

03

Wiring harness application

Wire harnesses are widely used in various fields. In the power industry, wire harnesses are widely used in transmission lines, substations and other facilities to provide stable power transmission for the power system; in the communications industry, wire harnesses are used in telephone lines, network lines, etc. to achieve high-speed transmission of information; in the automotive industry, Wire harnesses are used in various electrical equipment of automobiles, such as engines, lighting systems, navigation systems, etc., to provide power and information support for automobiles.

04

Development of wiring harness

With the continuous development of science and technology, wire harness technology is also constantly improving. From the original single wire to the current multi-core cable, from simple bundling to complex connector structure, wire harness technology has achieved remarkable results. In the future, wire harness technology will continue to develop towards higher performance, more environmental protection, and more intelligence.

higher performance

The performance of the wiring harness will be further improved. As equipment has higher and higher requirements for power and signal transmission, wire harnesses need to have higher conductive properties, lower signal loss, and better anti-interference capabilities. In addition, the weight and volume of the wire harness also need to be further reduced to adapt to the development trend of lightweight and compact equipment.

More environmentally friendly

Environmental protection will become an important development direction of wire harness technology. As people's awareness of environmental protection continues to increase, the selection of wire harness materials and manufacturing processes will pay more attention to environmental protection performance. For example, recyclable materials are used to manufacture wire harnesses, reducing the use of harmful substances, improving resource utilization, etc.

Read More

network supported

network supported